Production Engineering.

Skaraverken´s production engineers have extensive experience of all types of cutting and tooling machinery and expert knowledge in the most modern techniques and applications.

Whether sketching up a prototype or design in CAM or Cad systems or modifying a component to suit a changing requirement, our engineers are adept at finding the most efficient and effective solution to any challenge. At Skaraverken we get involved at the earliest possible stage of each project in order to establish the type of productive dialogue that helps illuminate the best possible methods and strategies.

The best of the past, the best of the future.

Technology changes constantly, and these changes often bring more efficient and more accurate machine developments. We are constantly investing in new equipment where needed or valuable to a specific process, such as our recent purchase of an advanced measurement machine that enables the fastest possible evaluation when bringing new products into production.

This does not mean that we invest unnecessarily, however. In fact, no one is better than Skaraverken at using older equipment to the best possible advantage, and we are big fans of the saying “if it’s not broke, don’t fix it”. This approach results in savings that we can pass on to our customers.

The Lean Approach to Production.

Skaraverken has adapted to a Lean production process, carried out with the help of both theoretical reviews and practical exercises. Today, we have a well-functioning process, encompassing morning meetings in all departments as well as a factory meeting for all employees as well as weekly improvement meetings for each department. This way of working has been much appreciated by both customers and co-workers alike and has resulted in a higher awareness and concern about what is happening in the company and the products we make. In addition, we use a Toyota model called QMB (Quality Management Board) for complaint management, which has helped us to more than halve the number of complaints.

Assembly.

No matter how perfect a component may be, if it is not properly installed it is worthless.

An important part of Skaraverken´s processing chain is the assembly of components and products, both those we purchase and those we manufacture ourselves. We manage thousands of different article numbers every year and it is not unusual for our products to encompass over two hundred different part numbers. Working successfully with a product array of this size requires knowledgeable personnel and well-developed logistics.

Many of the products that we assemble must also be tested in various test equipment, and test results digitally linked to an individual number on the product. In addition, we often pack products in the customer´s own packaging, which enables our customers to distribute their products directly to the end customer, but places even more demands on the production partner.

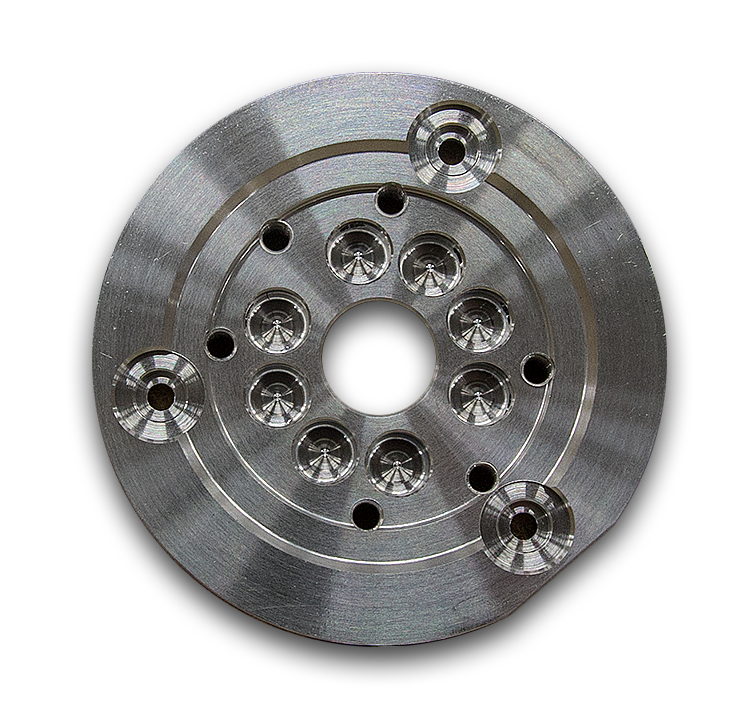

Machining.

Skaraverken has an extensive machine park, which allows us to offer a wide range of machining methods and techniques.

Turning.

The machine park consists of bar-type automatic lathes from Traub and multi-operational lathes from both Nakamura, Doosan and Mazak.

Milling.

Our machine park consists of both horizontal and vertical multi-operational and automated machines. We have an FMS facility from Fastems with two machines from Okuma. In addition, we have a 10-pallet machine from Okuma as well as a vertical machine from Doosan and a vertical machine from Mazak.

Grinding.

We are even well equipped on the grinding side, we are well supplied with machines for plane, internal, external, and center-less grinding. Several of the machines are equipped with remote control and are equipped with four spindles.

Gear cutting.

We have machines that can make both splines and cogs. We have two small spline shapers where we can remove internal diameters. In addition, we have four older gear cutting machines as well as a modern gear slotting machine with advanced controls that can manufacture straight cogs.

Machine Park.

Our extensive machine park covers everything from multi-operational machines for turning, grinding and milling, to multi-function machines for turning and milling, gear machining, assembly, and testing. Most of our machines are automated. Our machine park includes.

Vertical Milling machines

Mazak VTC-200C MK-II, Vertical

Doosan DNM 500

Horizontal Milling machines

Okuma MA-50HB, 10-pallets

Okuma MA-400HA, integrated in FMS (Fastems)

Okuma MA-400HA, integrated in FMS (Fastems)

Turning centers

Mazak Multiplex 620, robot

Mazak Multiplex 620, bar feed

Mazak Super QuickTurn 15MY

Mazak Super QuickTurn 200MY

Mazak Integrex 30

Mazak Integrex 300NSY

Mazak Integrex 200Y (2)

Mazak Integrex 100YB

Mazak QuickTurn 10, bar feed

Turning centers

Mazak Integrex 200SY, robot(2)

Leadwell LTC-15, bar feed

Traub TNS-42D (2) , bar feed

Traub TNC-65 (4), bar feed

Arboga-Darenth Central cooling liquid system

Doosan Puma MX2100 LST (2) one equipped with ABB-robot

Nakamura 100, bar feed

Nakamura 150, bar feed

Gears

Hobbing machine Pfauter RS-00 S

Hobbing machine Pfauter P-160

Gearhobbing Lorenz SN 4 (3st)

Gearhobbing Lorenz SNJ 5

Gearhobbing (CNC) C.L.C 200 SZ

Broaching machine Colonial Thule

Broaching machine AMT-Odin 8-1300

Grinding

Grinding machine Voumard 200 CNC

Grinding machine Voumard 150 CNC (2st)

Grinding machine Kellenberger RS 125/4

Grinding machine Studer S31

Center less Lidköping CL-2

Center less Lidköping CL-4

Honing machine Sunnen ML 2000 CGMIAX

Deep hole drilling department

Deep hole drill machine SIG B17/05

EDM department

Hsiu Fong CNC 462

Measuring

CMM CEJ Cordimatic 8000

CMM Etalon Derby 454

CMM DEA Global Silver Performance